Lokta Paper

-

Small Paper Flags

$ 7.99 -

Large Paper Flags

$ 9.99 -

Leafy Infinity Notebook

$ 11.99 – $ 14.99 -

Floral Lantern

$ 19.99 -

Leafy Lantern

$ 19.99 -

Buddha Lantern

$ 19.99 -

Animal Lantern

$ 19.99 -

Golden Ganesha Notebook

$ 11.99 -

Tie Dye Notebook

$ 14.99 -

Tie Dye Combo Pack

$ 89.99 -

Traditional Hand-Painted Notebook

$ 19.99 -

Traditional Hand-Painted Combo Pack

$ 99.99 -

Patterned Infinity Notebook

$ 11.99 – $ 14.99 -

Small Patterned Notebook

$ 11.99 -

Bodhi Leaf Notebok

$ 14.99 -

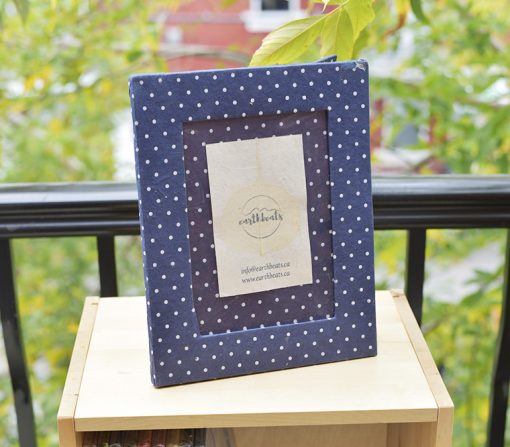

Picture Frames

$ 12.99

Lokta shrubs (Daphne bholua, Daphne papyracea) can be found scattered throughout the foothills of the mighty Himalayas of Nepal. These shrubs grow abundantly between the elevations of 2,000 to 4,000 meters and it is their starchy, inner bark that is used to create the paper products you see here. The raw lokta must go through several important steps before it hits the shelves however.

The plants are collected from the forest by cutting the stem at ground level. This allows for plant regeneration, which occurs approximately every 2-3 years with lokta plants. Next, the bark is stripped out of the stem and chopped into small pieces before being soaked in water for several hours. After the soaking has occurred, it’s time for an intensive washing process. The lokta bark pieces are boiled for 2 hours and then rinsed in cold water. The wet bark is then hammered into a pulp and poured into a wooden frame. The pulp is allowed to dry in the frame completely before being removed. The result of this process is raw, off-white lokta paper sheets.

What happens next depends on the final product. Since the result of the above process is un-dyed white paper, it is sometimes necessary to send the lokta sheets to a dyeing factory. Here, the sheets of raw paper are dipped into vats of colours and left to dry. The result is a vibrantly coloured, textured piece of paper. From here, the finished sheets go to another factory, their last stop before the store shelf.

At the final factory, the sheets of paper are transformed. A group of dedicated and creative men and women manipulate the raw paper into beautiful products. This process includes cutting and sizing the paper, creating the designs and using a variety of methods to implement them. Everything from braiding, folding, screen printing, and collage are used to create the products you see here.